Off-site contractor leverages digital twin, advanced materials

7 min read

Development contractors are correct now broadly adopting organization and manufacturing technologies that generate incremental efficiency improvements and generate electronic workflows across the dispersed team of owner, contractor, subcontractor and designer organizations that collaboratively supply construction.

A $400 Million Series D funding spherical for San Francisco-based mostly off-web page residence builder Veev may well, having said that, supply a glimpse of a much more radical transformation of the sector to occur. Veev’s solution to the lifecycle of residential created assets drives threat and environmental effect out of development, the decades of procedure and the close of a building’s effective lifetime. The round introduced now was led by Bond Capital, and need to aid Veev scale further than its present-day geographic footprint to new geographic marketplaces.

Funding Offsite Design Growth

In a movie job interview with ForConstructionPros in the times prior to the announcement, Veev Co-Founder and CEO Amit Haller explained the organization prepared to use the money to extend outside of its latest solitary variable in Northern California, incorporating a different in Southern California and then, in the system of 2023, expand into Texas.

“The strategies are for substantial expansion,” Haller said. “There is a 7 million property lack. We are not involved with competing with other off-website builders. We will all mature as our generation amounts boost. We are all just striving to solve this housing scarcity problem. There is no single player that can move the needle on this problem by yourself.”

Though expansion opportunity in household building is significant, there is no technological barrier to Veev’s technique coming into gentle industrial or place of work development.

“We are not minimal to residential when it comes to our structural elements,” Haller explained. “We are already business-ready. The system as it is ideal now is just limited to up to 8 tales or 85 feet because of to fire scores. We can make lodges, light business or place of work properties. Our emphasis on household is coming from our mission statement—this is a disaster we are going through when it will come to housing selling prices, higher expense and a scarcity. There is so substantially work for us for the rest of our life.”

The enterprise plans to go to marketplace by huge-scale residential enhancement firms into the foreseeable future—those constructing in between 50 and 100 one spouse and children, condominium or apartment models, right until they have the scale to interface instantly with household dwelling buyers.

“The business product is that we will come to be a structure-develop normal contractor off-web site,” Haller explained. “So we will get the plan for the project, transform it into the electronic twin in our system—we have our individual proprietary electronic twin method. It will be our architect and structural engineers on file, which are personnel of the company. And then we fabricate it, deliver it and set up it and will also agreement to preserve it down the highway. So we will take on the overall conclusion-to-stop obligation of the job.”

Veev’s recent manufacturing facility is between 50,000 and 100,000 sq. toes, and can generate about 800,000 sq. feet of living house for each year, per Haller. He stated the company’s program is to expand by developing additional facilities upcoming to populace centers with significant desire, related to Amazon’s solution to locating logistics and warehouse centers.

Veev’s Northern California production facilityVeev

Veev’s Northern California production facilityVeev

Greening the Constructed Asset Lifecycle

Aside from the prospect of high progress, Veev might be an desirable investors or funds concentrating on the surroundings, sustainability and company governance (ESG). According to Reuters, $649 billion was invested in ESG-centered resources all over the world previous year through November 30, up pretty much 20 percent in excess of the 2020 and 227 % above 2019.

The enterprise relies on resources that are environmentally friendly in their power performance, over-all carbon footprint and finish-of-lifetime impacts. Assignments are delivered with a sensible residence mechanical program and lower voltage lighting, reducing lifecycle environmental effects. The business also recently declared a internet-zero commitment to the Earth Environmentally friendly Building Council.

Veev’s material collection, which is composed generally engineered large performance area (HPS) supplies and steel, make 47 per cent less CO2 emissions than standard design supplies, in accordance to Veev. These products are configured into pre-crafted steel-bolstered panels to be assembled on site. This creates possibilities to reduce the environmental footprint of building and the asset lifecycle considerably even as opposed to precast concrete, or other techniques to offsite construction.

“The locations we are borrowing our concepts from are semiconductors on the micro stage and aerospace style on the macro amount,” Haller said. “Our structural integrity is coming from mild gauge steel, which is way stronger than wood, lighter and more sustainable. We are using 100 per cent recycled steel. Our insulation is an superior product from the foam field. Spray foam is currently being employed broadly in the business and we all know its positive aspects, but each individual of our panels have foam built in and comes insulated and waterproofed.”

But it is in the use of HPS cladding exactly where Veev’s method to components is potentially most groundbreaking.

“In the interior, in its place of working with drywall, we are basically making use of HPS,” Haller claimed. “This is the identical loved ones of materials as sound surface area elements like Corian. A lot of folks never know this, but this product was invented not for counter tops, but for surgical suites in purchase to create partitions that are antibacterial and maintenance no cost permanently.”

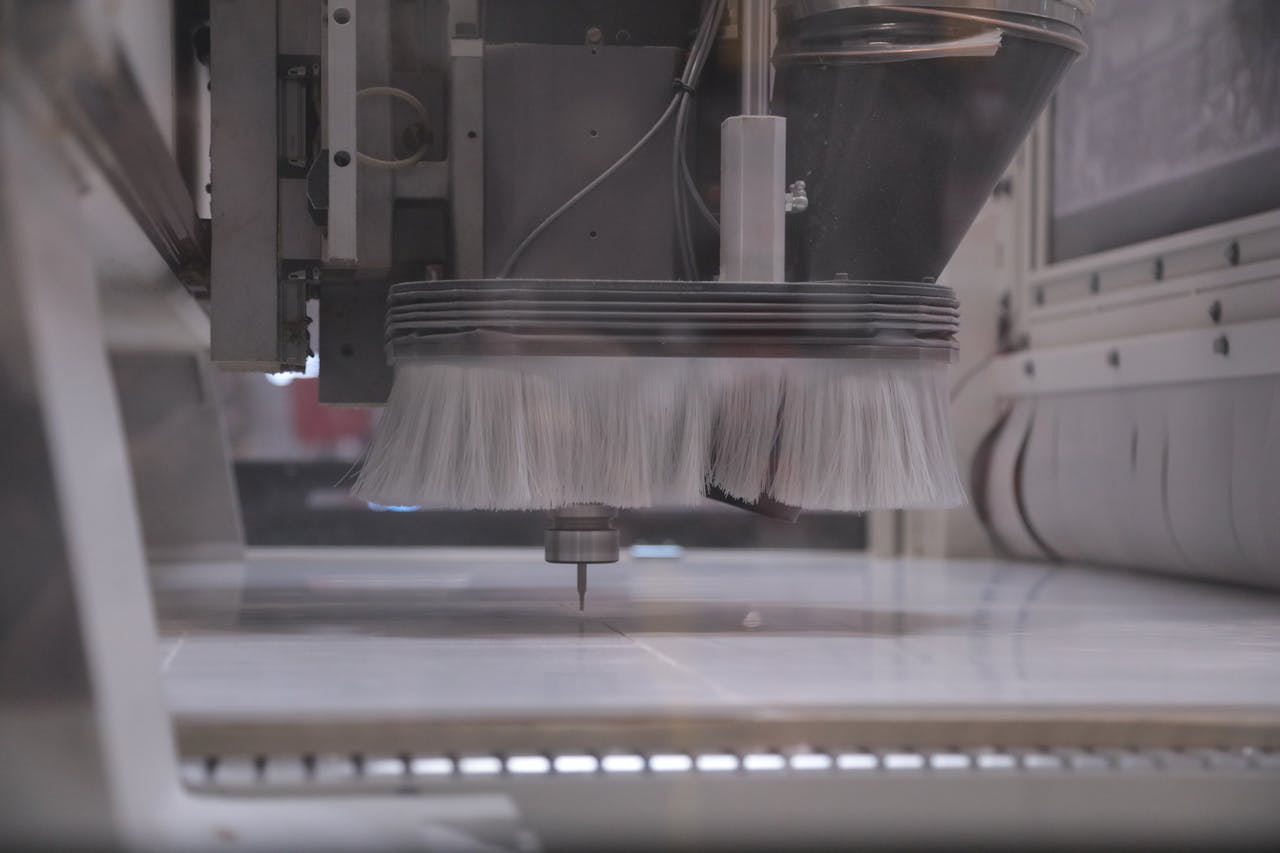

Veev depends on highly developed etching and printing technological know-how to completely transform this one substance for several works by using in the structure.

“One of the most critical strategies of the company is that practically everything finishing, interior, exterior, kitchen area cabinets, even bathroom flooring, is finished with the exact same content,” Haller mentioned. “The very same HPS. This substance often will come in white plates and will go by means of processing internally in our fab shop which will accomplish 3D texturing. We will change it to seem and experience like anything—the exact same product can glance and come to feel like mahogany wood, ceramic tiles or exterior stucco or marble or anything you want it to be. We have established an infinite electronic stock, so our provide chain is a electronic provide chain so you can have any look and sense you like.”

Significant functionality surfaces are remodeled into several textures and appearances.Veev

Significant functionality surfaces are remodeled into several textures and appearances.Veev

HPS substance is etched in Veev’s Northern California production facility.VeevDigital Twin and Offer Chain Innovation

HPS substance is etched in Veev’s Northern California production facility.VeevDigital Twin and Offer Chain Innovation

The reliance on a tiny amount of components permits Veev to regulate its source chain, and its division of labor in the area also limits its publicity to labor shortages.

“Offsite building is not sufficient,” Haller said. “Because with offsite, you have the very same difficult provide chain as on-web-site, just in a diverse site. The similar issues, the exact 10,000 SKUs in the provide chain, the similar framer, the exact painter. Sure, it is a very little bit additional robotic, there is a minor bit additional automation and there is a far better-managed atmosphere. There is some advantage to offsite, but it is not a recreation changer. To be a recreation changer, you require to believe about new supplies. And a digital twin is a should.”

The enterprise has designed its have electronic twin software that allows developers or dwelling purchasers to digitally walk by a job, visually approving the glimpse and experience and layout. The electronic twin then drives the fabrication approach for panels to be assembled on-site. Panels arrive on website with all mechanicals and home windows installed, significantly decreasing the have to have for qualified tradespeople on the task web site.

“Architects and engineers now attract designs for development men and women,” Haller said. “We require to start out creating ideas for machines—for manufacturing folks, not for construction people. That is our issue. Development men and women are at a lack. Creating extra programs for development individuals that do not exist is not likely to resolve the difficulty.”

The digital twin and restricted command in excess of development tolerances and elements employed in design will also permit streamlined routine maintenance, alternative and remodeling.

“See that cupboard driving you?” Haller questioned for the duration of the video job interview. “What if you want to replace that? You will need to convey in a contractor who will evaluate the doorways, determine what hinge is used, specify price tag to maintenance or swap it with what you want. Probably the measurements are not precise, and they have to begin once again. With our households, we know the exact proportions, have the aspect range for the hinge and can deliver whatsoever you want with no guesswork.”

Bottom LINE: Haller claims Veev’s technologies will not be licensable by other contractors in the foreseeable potential, but in time, other residential and gentle commercial contractors could consider edge of their integrated offer chain and state-of-the-art technologies. But even as construction company source arranging (ERP), estimating program, area productiveness technology and products automation are digitizing the cow paths contractors have typically observe, Veev’s vision of the upcoming is a little something to hold in mind as a likely final vacation spot for the market.

.jpg)